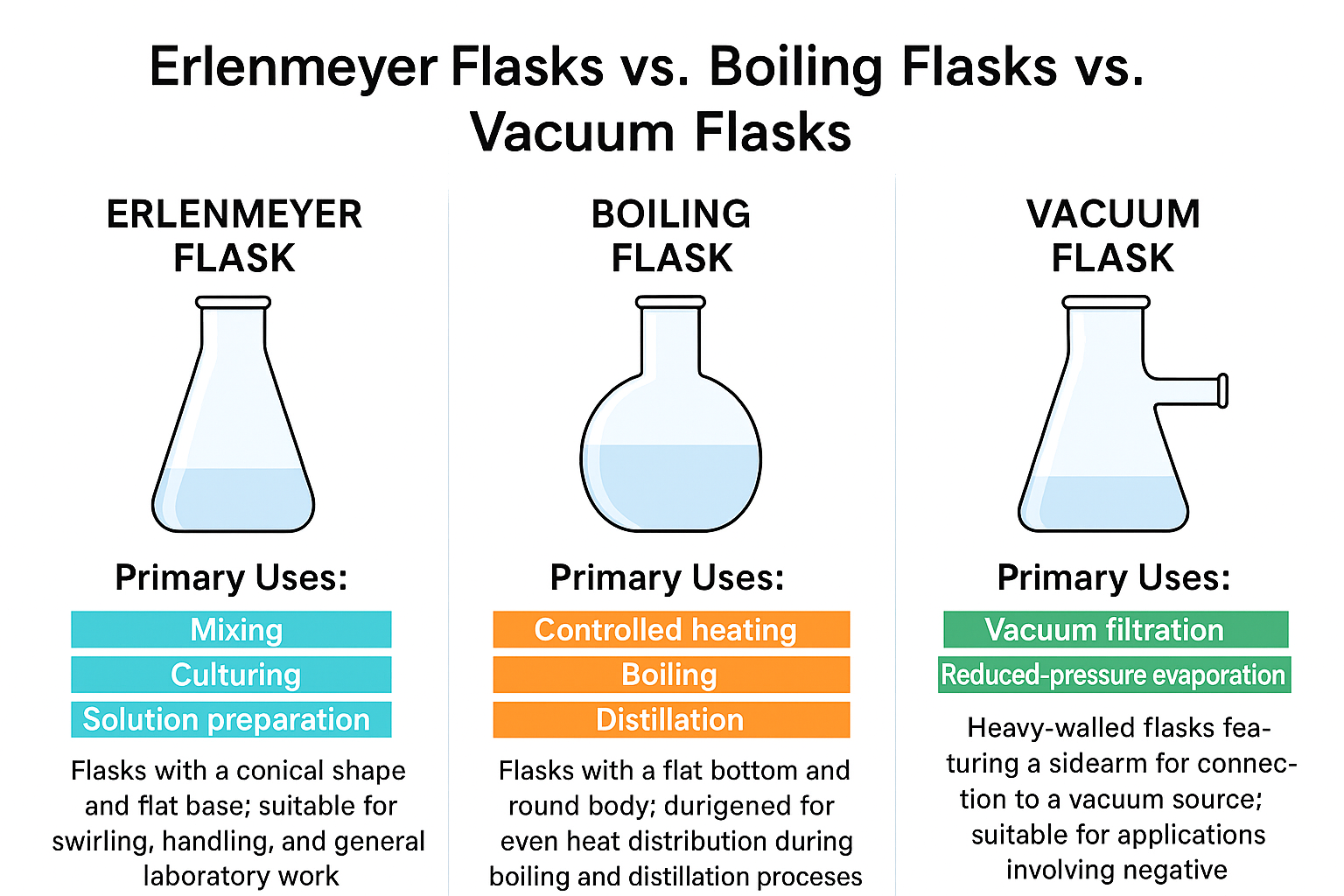

Erlenmeyer Flasks vs. Boiling Flasks vs. Vacuum Flasks: Key Differences and Laboratory Uses

In any chemistry or biology laboratory, glassware is fundamental to daily operations. Among the most versatile and widely used pieces are Erlenmeyer flasks, flat‑bottom boiling flasks, and vacuum flasks. Though they may appear similar at a glance, each is engineered for specific types of work, offering advantages in mixing, heating, distillation, or filtration. Understanding these distinctions helps scientists choose the right tool and maintain both safety and accuracy in lab settings.

What Is an Erlenmeyer Flask?

Shape, Design, and Unique Features

Erlenmeyer flasks are characterized by their conical body, flat bottom, and narrow neck. Developed by Emil Erlenmeyer in 1860, their sloped sides greatly reduce splash‑back when swirling liquids. This makes them an excellent choice for everyday laboratory mixing and handling.

Common Laboratory Uses for Erlenmeyer Flasks

- Mixing and swirling solutions

- Microbial culturing (with cotton plugs or foam stoppers)

- Dissolving solids

- Titrations

- General reagent preparation

Because they sit flat, these flasks are ideal for benchtops, hot plates, or incubator shakers. However, they are not optimized for high‑temperature boiling due to uneven heat distribution and thicker glass walls.

What Is a Flat-Bottom Boiling Flask?

Design Advantages for Heating and Distillation

Flat‑bottom boiling flasks (a round‑bottom flask variant) are designed for even heat distribution, a critical feature during boiling and distillation. Their spherical body allows heat to pass uniformly through the solution, minimizing hotspots and reducing bumping.

The flat bottom offers stability on benches without requiring a cork ring—though clamps are still recommended for safety.

Typical Uses for Boiling Flasks in the Lab

- Controlled heating

- Boiling solvents

- Reflux systems

- Distillation setups

- Organic synthesis

Multi‑neck versions allow for thermometers, condensers, or nitrogen lines. Compared with Erlenmeyer flasks, boiling flasks are vastly better suited for high‑heat applications.

What Is a Vacuum Flask (Büchner Flask)?

How Vacuum Flasks Are Built for Negative Pressure

Vacuum flasks—also known as Büchner flasks or filter flasks—feature glass walls significantly thicker than other flask types. A small sidearm allows attachment to a vacuum pump, enabling the flask to withstand internal pressure changes without imploding.

These flasks are engineered for mechanical durability, not thermal insulation (unlike consumer thermos-type vacuum bottles).

Common Laboratory Applications for Vacuum Flasks

- Vacuum filtration using a Büchner funnel

- Reduced‑pressure evaporation

- Solvent recovery setups

- Low‑pressure distillation

Because pressure stress increases the risk of breakage, vacuum flasks must be routinely inspected for chips or cracks.

Side-by-Side Comparison of Flask Types

Erlenmeyer Flasks

- Best for mixing, culturing, dissolving, and handling

- Flat bottom and conical shape ideal for swirling

- Not suitable for high-temperature distillation or vacuum work

Flat-Bottom Boiling Flasks

- Best for heating, boiling, refluxing, and distillation

- Round body ensures even heating

- Often used with heating mantles or oil baths

Vacuum Flasks

- Best for vacuum filtration and reduced‑pressure evaporation

- Thick-walled, stress-resistant design

- Essential for setups involving vacuum pumps

Choosing the Right Flask for Your Laboratory Work

A well-equipped laboratory needs all three flask types, as each excels in different scenarios. Erlenmeyer flasks are the everyday workhorse; boiling flasks dominate heating and distillation; and vacuum flasks serve essential roles in filtration and pressure‑controlled processes. Knowing their differences ensures safer, more efficient, and more reliable experimental results.